As a versatile tool, spray bottles have a wide range of applications, covering gardening, cleaning, medical, cosmetics and personal care. The design of spray bottles is not only to meet daily needs, but its core component, the flow channel shape of the nozzle, has a profound impact on the spray effect, which is worth in-depth discussion.

The selection of spray bottle nozzle flow channel shape is the key to optimizing the spray effect. The physical properties of the liquid, the spray pressure and the specific spray requirements should be considered during the design. Common nozzle flow channel shapes include linear, diffuse, tapered and conical, and each design has its own unique application scenarios and advantages and disadvantages.

The design of the linear flow channel is simple, the flow channel cross section remains constant, and the fluid flows at a uniform speed. This design is suitable for applications that require stable spraying, such as certain chemical experiments or medical devices. However, due to its single spray effect, it may not meet the diverse spray needs.

The design of the diffuser flow channel gradually increases the flow channel cross section, so that the fluid forms a wider coverage when it is sprayed, and the spray is more uniform. This design is common in occasions such as gardening fertilization and cleaning and disinfection. By adjusting the diffusion angle and flow channel length, the spray effect can be further improved to adapt to different application needs.

Compared with the diffuser type, the design of the tapered flow channel is that the flow channel section gradually decreases, which can effectively increase the injection speed and pressure of the fluid and enhance the penetration of the spray. This design is suitable for occasions such as high-pressure cleaning or cutting that require high-speed injection, but it should be noted that the spray uniformity may be affected and appropriate adjustments are required during use.

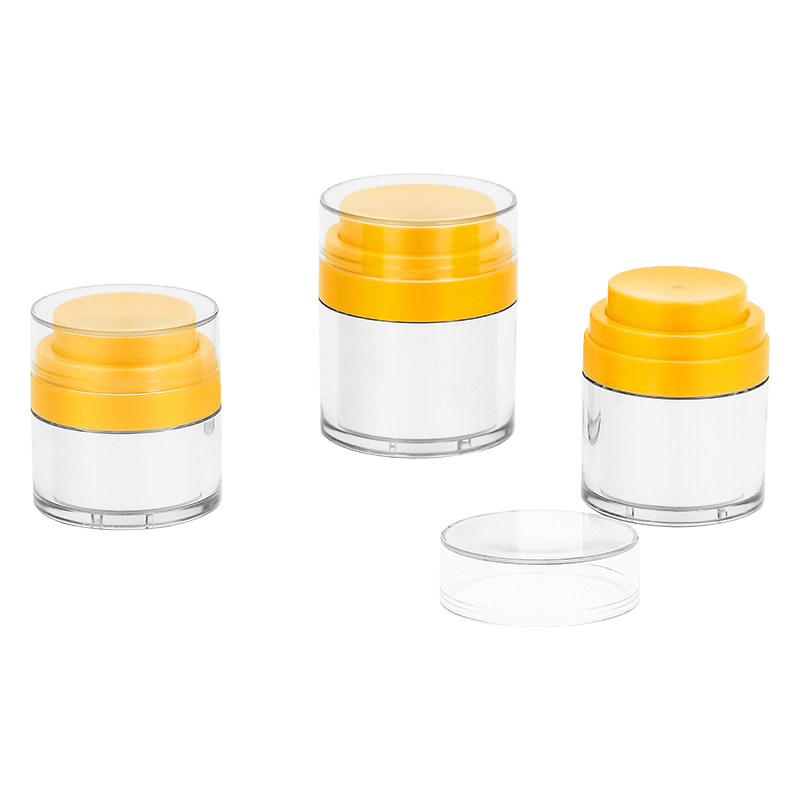

The conical flow channel is a compromise design, and its flow channel section gradually changes from the inlet to the outlet, which can strike a balance between the injection speed and the coverage. This design is suitable for applications that need to take into account both the injection speed and the coverage, such as cosmetic sprays and personal care products.

In addition to the above common flow channel shapes, there are also special designs such as spiral and wave shapes on the market. These special flow channel shapes can change the flow state of the fluid and create a unique spray effect. For example, the spiral flow channel allows the fluid to form a rotating spray when it is ejected, increasing its diffusion and uniformity, while the wave-shaped flow channel can produce a wavy spray, making the spray more delicate and soft.

The choice of flow channel shape not only affects the coverage, uniformity and penetration of the spray, but is also directly related to the spray cone angle and the distribution of spray particles. The spray cone angle is the angle of the cone formed after the spray leaves the nozzle. Different flow channel shapes will produce different cone angles, which in turn affects the coverage of the spray. The distribution of spray particles refers to the distribution of different particle sizes in the spray. This characteristic is directly related to the effect and application scenarios of the spray.

中文简体

中文简体 English

English русский

русский